Swiss type turning has a long-lasting tradition of achieving precision and productivity for manufacturing in medical and electronics industries. During the past decade applications of Swiss type machine tools have expanded rapidly to other industries, including automotive and aerospace. Manufacturing of fashion and apparel ornaments and prestigious watches are other examples. The flexible methods to use offsets on workpiece, use of several reference frames for programming cutting tools, automatic handling of stock material between spindles, utilization of guide bush for raw material positioning and automatic removal of finished workpiece form machine has encouraged shop floors around the globe to utilize Swiss type machine tools for existing as well as new applications for producing not only long and slender workpieces but also for parts which are thin and circular in shape.

Highlights

- 5-axis interpolator

- Continuous profiling of feedrates

- Tool compensation

Benefits

- Reduction of dynamic deflections up to 70%

- Reduced finishing time by up to 40%

- Increased surface quality by up to 35%

- Reduction of vibration-caused tool failure and tool wear by up to 30%

- Reduction of reject rates

Overview

The expanded applications have at the same time introduced producers of Swiss type machine tools to a new set of requirements for the control and programming of machine tools. The intent of designer in developing high value and prestigious products, which at times are one of a kind model, has increased the complexity to produce these designs due to introduction of freely formed shapes into design.

Since the founding of Tornos in 1914, the company has pioneered in sliding headstock technology. They manufacture CNC sliding headstock automatic turning machines, cam- or numerically controlled multi-spindle machines, and machining centers for complex workpieces requiring high-precision machining, all backed by their own software and services. Tornos is also faced with the challenge to manufacture from their machine tools the new increasingly complex shaped designs.

Highlights

- 5-axis interpolator

- Continuous profiling of feedrates

- Tool compensation

Benefits

- Reduction of dynamic deflections up to 70%

- Reduced finishing time by up to 40%

- Increased surface quality by up to 35%

- Reduction of vibration-caused tool failure and tool wear by up to 30%

- Reduction of reject rates

Since the founding of Tornos in 1914, the company has pioneered in sliding headstock technology. They manufacture CNC sliding headstock automatic turning machines, cam- or numerically controlled multi-spindle machines, and machining centers for complex workpieces requiring high-precision machining, all backed by their own software and services. Tornos is also faced with the challenge to manufacture from their machine tools the new increasingly complex shaped designs.

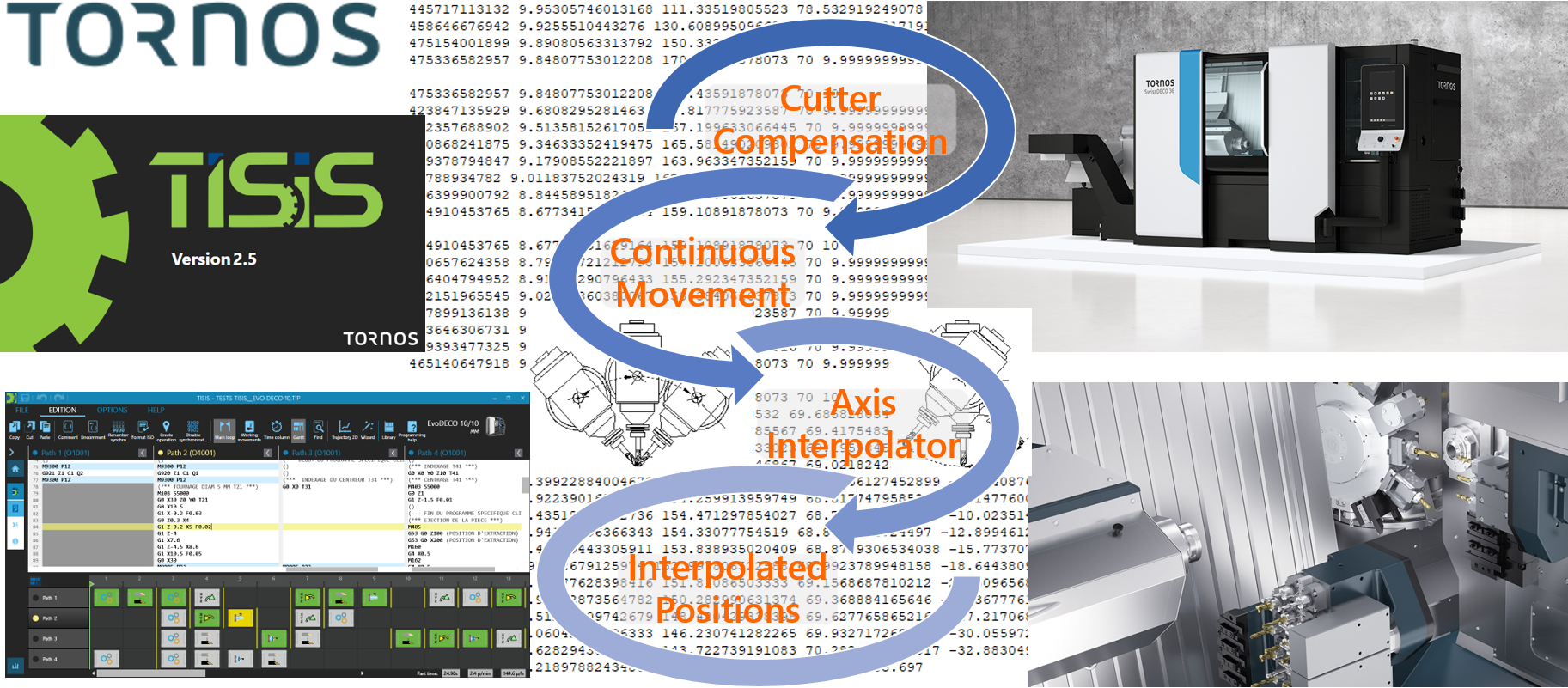

In order to investigate and develop solutions to overcome the challenges of new requirements, Tornos invited the experts from research and development and industry to collaborate on the development of their advanced machine tool model. The focus of the collaborative developments was to extend the functionalities of the machine tool programming software TISIS and enhancements of data structures which should also be supported by selected Fanuc machine tool. The objective of these enhancements is to realize the simultaneous 5-axis machining process through the movement of rotary machine tool axes both in interpolated and non-interpolated modes. These advances have enabled Tornos machine tools to support simultaneous multi axis turning as well as multi axis milling along with the traditional Swiss type machining in the same machine tool.

ModuleWorks as the leading provider of software for simultaneous 5-axis milling and turning provided software modules which included its toolpath planning and postprocessing algorithms to solve the challenges faced by Tornos. The integration of results of research and development was carried out by Fraunhofer IPA. The incorporation of software modules from ModuleWorks into a new and enhanced 5-axis interpolator was taken up by AixPath. AixPath is a software development company from Aachen Germany and was established as a spin-off of Fraunhofer IPT and ModuleWorks. AixPath is also an official Technology Partner for Siemens Digital Industry Software. AixPath has collaborated with ModuleWorks in several technology intensive projects and has a large experience of developing customized and integrated software solutions for complex manufacturing processes.

The schematic diagram above elaborated the integrated operation and functionalities of enhanced 5-axis interpolator software developed by ModuleWorks and AixPath. The software provides a bridge between the Tornos programming software TISIS and selected Fanuc machine tool controller. The 5-axis interpolator communicated through standard interfaces for programming and data standard. Its integration into the CAx-chain for programming of Tornos machine tools is also carried out as part of software integration and deployment activity. New 5-axis interpolator provides a continuous profiling of feedrates which abide by the limits set by the capabilities in terms of dynamics of individual machine tool axis of both types, linear and rotary. The enhanced 5-axis interpolator works as an option both in rotational and interpolated movement of tool center point to achieve 5-axis movements of tool. Tool positions are compensated by the radius of cutting points. The output from 5-axis interpolator are the interpolated positions synchronized to the interpolation cycle of Fanuc controller.

The software solutions have gone through intensive testing and trials which included machining of raw materials on prototypes of SwissDECO machine tool. The software is part of a software package deliver+ed with new machine tools. The new 5-axis interpolator has enhanced the software platform which is the basis of TISIS software. In the future more machine tools models will benefit from these implementations. ModuleWorks and AixPath are further involved in the life cycle development of integrated software solutions for Tornos.

About Tornos Group

Tornos Group is one of the global leaders for the development, production and distribution of Swiss-type automatic lathes and multi-spindle machines. The company’s history dates back to 1880, placing Tornos at the beginning of Swiss-type lathe technology. The Group primarily manufactures CNC Swiss-type (sliding headstock) turning machines, multi-spindle machines, and machining centers for complex parts requiring high precision. Tornos is headquartered in Switzerland. Through a global sales and service network, unique solutions are supplied to customers in dedicated market segments such as automotive, medical and dental technology, micromechanics, and electronics. With its 728 employees (FTEs), Tornos Group generated sales of CHF 214.9 million in 2018.

About ModuleWorks

ModuleWorks is the leading software component provider for the digital manufacturing industry. With over 200 employees and 900 man years of software development, ModuleWorks’ expertise in toolpath creation and simulation is recognized throughout the industry and its software components are already optimizing the performance and quality of over 500,000 installed seats of CAD/CAM and CNC software around the world. From standard products to exclusive development projects, ModuleWorks helps companies to bring their vision of Industry 4.0 to life. With its comprehensive portfolio of cutting-edge software components, ModuleWorks enables its customers to optimize their CAD/CAM solutions and connect to CNC/MTB systems to increase their competitiveness and help them get there faster.