The machine builders for additive manufacturing (AM) must provide systems that are robust, easy to operate, and economical to purchase and maintain. For a persistent application of laser powder bed fusion L-PBF AM machines must be flexible to adopt to advanced materials and new sets of innovative part designs.

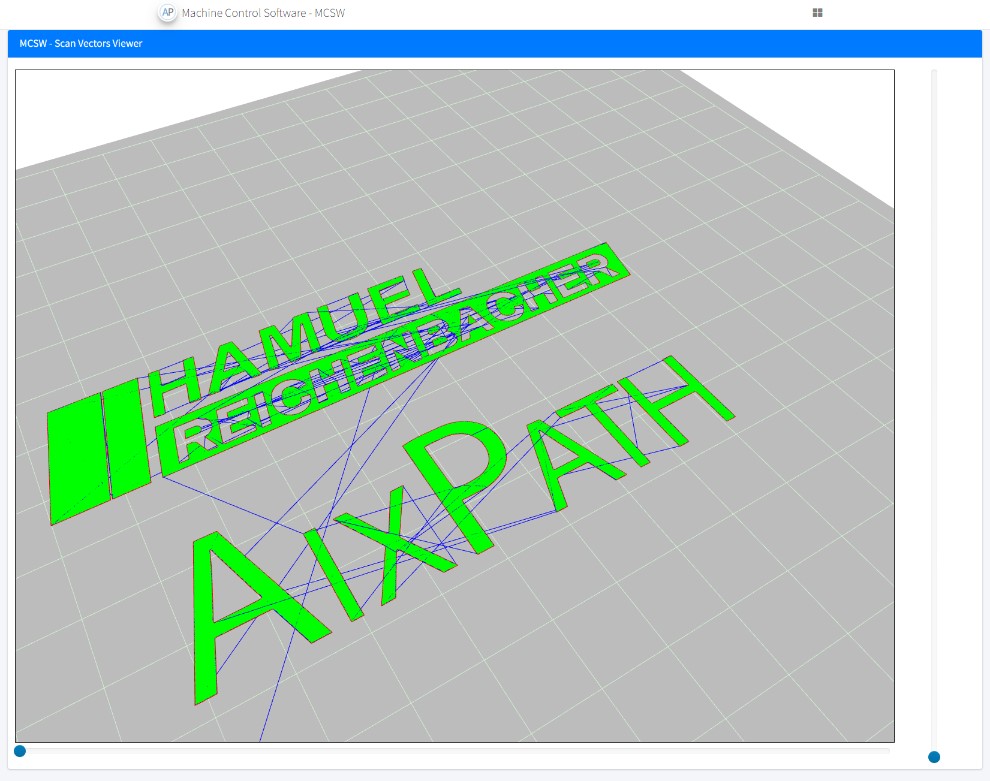

Siemens DI has a wide range of automation and digitalization systems for machine builders for AM. Systems for L-PBF are being enhanced by AIXPATH’s new MCSW – Machine Control Software. MCSW is developed in close cooperation between Siemens and AIXPATH. The software provides machine builders of AM a flexible way to develop control software of 3D printers for metal, polymers and other specialized materials. MCSW bridges gaps for end users in their CAD-to-Part chain and significantly reduces efforts for machine builders in software engineering.