CAx tools have become an integral part of a production environment providing the necessary degree of flexibility and efficiency to realize high quality products while keep manufacturing times and costs low. Meanwhile current products and parts increase in complexity, their requirements to quality and form accuracy as well as an in increase in the usage of conventionally hard-to-machine materials. Established manufacturing technologies like milling reach their technological and economical limits. Alternative manufacturing technologies with integrated manufacturing solutions can provide the necessary efficiency to cope with these challenges.

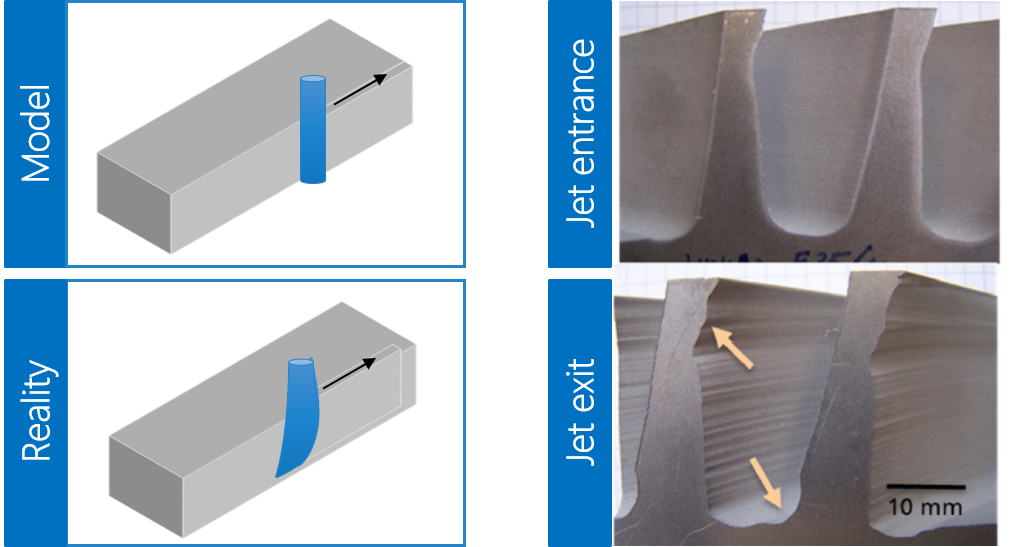

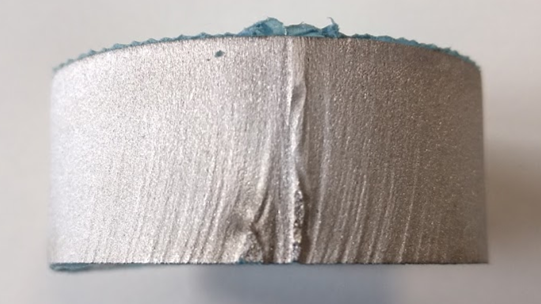

An alternative manufacturing technology for the machining of hard-to-machine materials is jet cutting. Jet cutting provides a highly flexible tool with a high cutting rate, which can be used to almost machine every material. Especially when it comes to machining of conventionally hard-to-machine materials or material combinations the technology abrasive jet cutting great advantages: The mechanical forces applied to the part are relatively small and no thermally induced changes occur in the material composition. In comparison to other alternative manufacturing technologies jet cutting has an increased flexibility realizing a multitude of different manufacturing tasks (e.g. cutting, milling or for cleaning of surfaces). Current water jet machines provide 5-axis capabilities and water pressures around 6000 bar. This development greatly broadens the scope of applicability of the water jet technology. However, software solutions for this technology, especially with the option to integrate them into existing process chains are not available on the market and currently state-of-the-art milling algorithms are being used for implementing water jet cutting process.