Our services for development and commission of flexible robot solutions provide all means to plan and implement sophisticated production processes. AIXPATH’s software solution supports programming and simulation of multiple robots, combinations of rail and rotation table. We also provide a plug-and play integration of peripherals into the robot control.

Our process experts are available to support you during planning, optimization, and execution of your robot-based manufacturing processes. Our solutions provide you with production ready robot programs and can be adapted to meet your specific production needs.

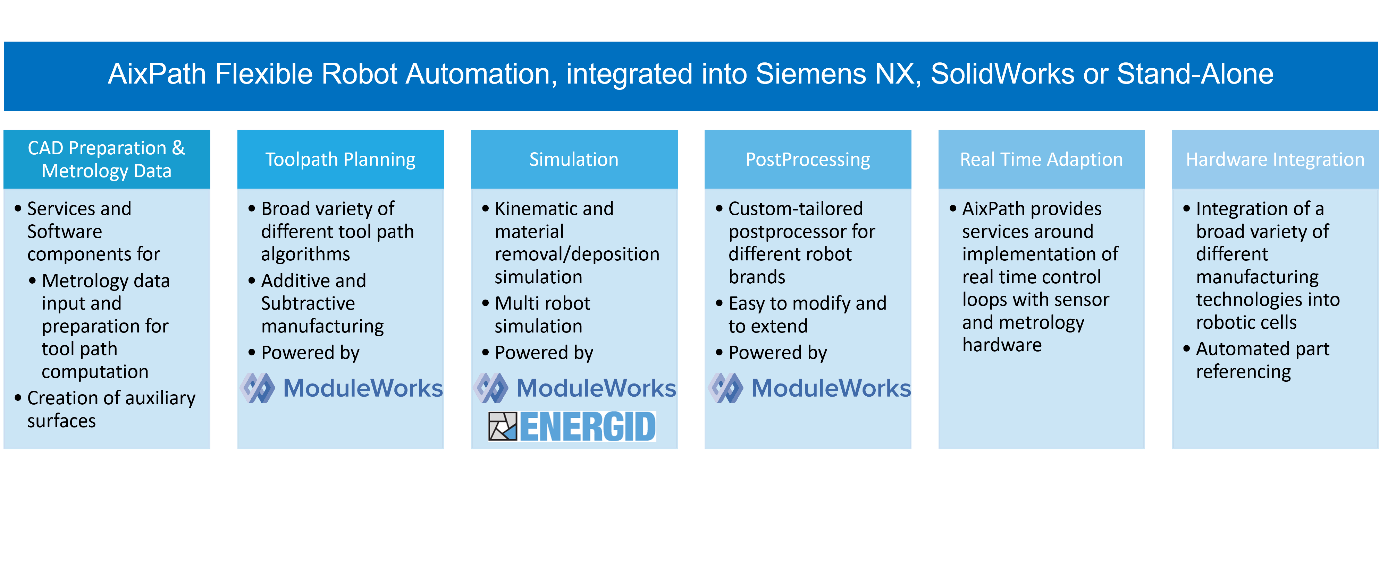

The flexible robot automation package from AixPath provides you with a set of core modules being able to cover the whole process chain. Our solutions are seamlessly integrated into the PLM-Systems Siemens NX and SolidWorks. However, an integration of said solution in other third-party applications is possible.

The flexible robot automation package integrated into a PLM-system provides all functionalities of a sophisticated CAM-application with a precise simulation which allows to perform collision and singularity avoidance as well as automated handling of such scenarios for several n-joint robots with external axes interacting with each other simultaneously.

The flexible robot solution package comes with a broad variety of different CAM strategies and patterns that allows the easy implementation of control loops taking process measurements into account. The computed tool path is then processed by our generic and flexible post-processor to output a production ready program. The postprocessor is an easy configurable tool allowing the user to adapt their syntax or output according to their needs. Also, the additional output of to the tool path points associated values, like process control values or additional commands for integrated peripherals are possible.