The efficiency of milling processes is a crucial topic in production as any deficits in process planning scale with the number of produced parts. While a lot of effort is put in improving quality and efficiency of the last finishing step, time-consuming roughing operations often lack efficiency. The potential for scalable improvement in this area is quite high but often lies idle. AixPath developed together with Boeing a High-Speed Adaptive Roughing (HSAR) CAM module as a plugin for Siemens NX, which implements a

Highlights

- CAM software for toolpath planning of roughing milling operations with high cutting speed

- PlugIn for the latest versions of Siemens PLM NX with NX native look and feel

- 2D and 3D geometry for toolpath planning

- HSAR supports usage of optimum machining process parameters data for a chatter free toolpath programming

Benefits

- Reduction of machining times for roughing operations (up to 40% machining time reduction for Titanium, up to 30% machining time reduction for Aluminum)

- Selection of the most efficient stable cutting parameters to allow chatter free machining

- Increased tool life for machining of hard metals

- Direct engagement into material with helix cutting or at pre-drilled

- Effective control over axial depths of cut for stable cutting conditions

Overview

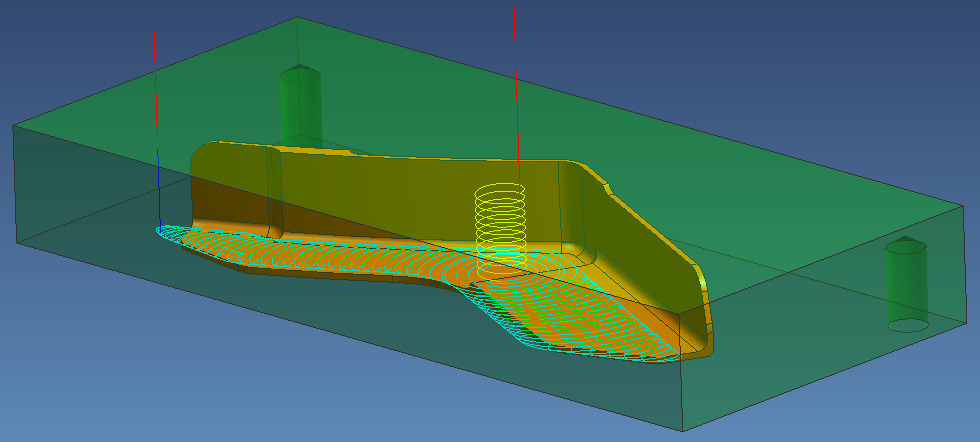

Roughing of freeform surface with HSAR module

Roughing of freeform surface with HSAR moduleunique algorithm for calculation of toolpaths for high productivity rouging milling. These toolpaths are designed to control engagement conditions between cutting tool and material in all situations of different geometric variations. The ability of the algorithm to control tool engagement against predefined conditions makes the calculation of toolpaths for highly productive methods of material removal possible. HSAR is fully integrated into the industry standard PLM software, Siemens NX and provides the capability to calculate high speed toolpaths for roughing milling of prismatic shaped parts using either the solid geometry designed in NX or their wireframe edges. HSAR module also integrates machining stability data to select most productive chatter free cutting conditions for a given combination of milling tool and machine tool. With the provided functionalities of the CAM module roughing operations while machining Titanium can be reduced by up to 40% and for Aluminum up to 30%.

Highlights

- CAM software for toolpath planning of roughing milling operations with high cutting speed

- PlugIn for the latest versions of Siemens PLM NX with NX native look and feel

- 2D and 3D geometry for toolpath planning

- HSAR supports usage of optimum machining process parameters data for a chatter free toolpath programming

Benefits

- Reduction of machining times for roughing operations (up to 40% machining time reduction for Titanium, up to 30% machining time reduction for Aluminum)

- Selection of the most efficient stable cutting parameters to allow chatter free machining

- Increased tool life for machining of hard metals

- Direct engagement into material with helix cutting or at pre-drilled

- Effective control over axial depths of cut for stable cutting conditions

Figure 2: Part made from Titanium after roughing milling programmed using HSAR plugin in Siemens NX

Figure 2: Part made from Titanium after roughing milling programmed using HSAR plugin in Siemens NXThe Boeing Company

The Boeing Company (TBC) USA is the world’s largest aerospace company and leading manufacturer of commercial jetliners, defense, space and security systems, and service provider of aftermarket support. As America’s biggest manufacturing exporter, the company supports airlines and U.S. and allied government customers in more than 150 countries. TBC products and tailored services include commercial and military aircraft, satellites, weapons, electronic and defense systems, launch systems, advanced information and communication systems, and performance-based logistics and training.