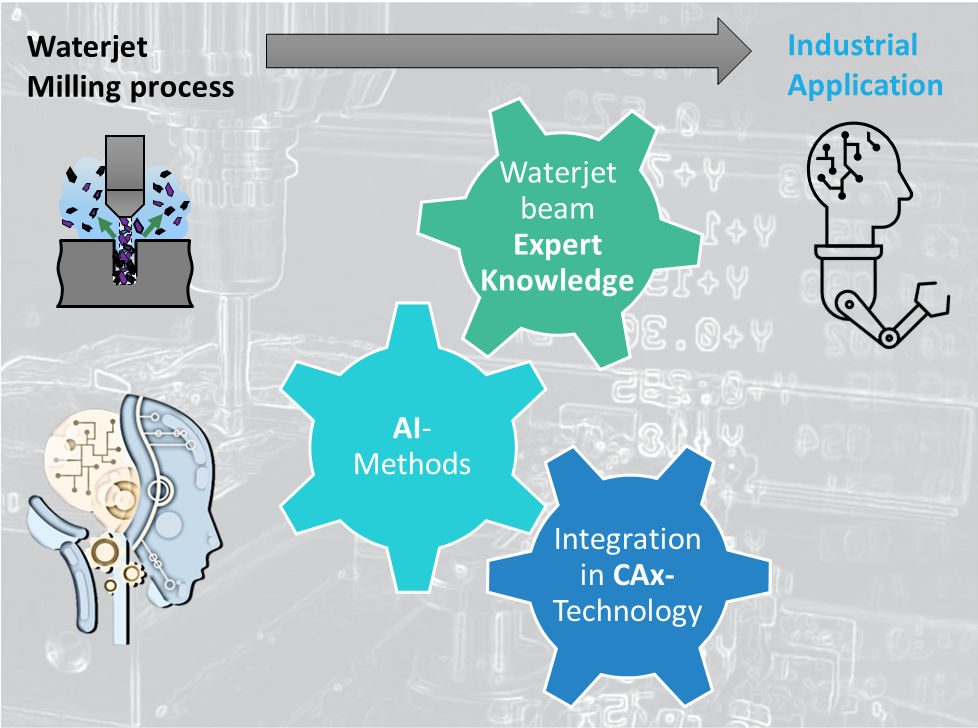

The application of high-pressure water jet nozzles has proven beneficial for parting thick objects made of almost any material. The use of abrasive materials, such as fine granite sand, is permitted and significantly increases the productivity of the cutting process. The benefits of lower setup time and higher productivity are allowing waterjet technology to find applications in new areas. AixPath has recognized the potential of using water jets to produce accurate final forms of complex-shaped parts, such as turbine blades or teeth. To fully realize the benefits of this new application, a new method for controlling and programming waterjet machines—referred to as “waterjet milling”—is needed.

Highlights

- Experts knowledge

- AI-model for process parameters

- Process Assistance

- Close integration of AI and CAx-Technologies

Benefits

- Knowledge preservation and systematic usage

- Increased reliability in process planning

- Reduction of programming effort

- Persistent quality in products parts

Funding Program

The “JetsKI” project is funded by the European Regional Development Funds (ERDF) and the Just Transition Funds (JTF) Program NRW 2021 – 2027 as part of the Innovationswettbewerb NEXT.IN.NRW (Funding Grant: EFRE-20800518)

Overview

In developing the new programming method, the challenge lies in achieving continuous control over the water jet so that only the necessary amount of material is removed—without cutting through the material. This objective is quite the opposite of how water jets are typically used in manufacturing. AixPath has started the project with the support of the research program EFRE.NRW.NEXT to develop a software solution for programming “waterjet milling.” HydroMill GmbH and the University of Bochum are research partners in the project.

Highlights

- Experts knowledge

- AI-model for process parameters

- Process Assistance

- Close integration of AI and CAx-Technologies

Benefits

- Knowledge preservation and systematic usage

- Increased reliability in process planning

- Reduction of programming effort

- Persistent quality in products parts

The high indeterministic behavior of the “waterjet milling” process does not allow for traditional CNC programming methods. To achieve the objectives of the project, artificial intelligence methods and models are applied. The project has a duration of three years. It was initiated by establishing a knowledge base for the waterjet milling process. This knowledge base is then used in combination with a neural network model to characterize workpiece geometries, providing process assistance for planning and programming the waterjet machines. The success of the project will determine the future course of action for a fully automated workflow, where experts will only need to interact with the system to expand the knowledge base for the process.