A crucial part for realizing an efficient manufacturing process in the context of industry 4.0 is the creation of a precise virtual image of the process chain and the current state of the part along the process chain. Current software systems cannot fulfill the quality requirements regarding the geometric representation of the part, whereby several applications for process optimization cannot be used, which hinder the creation of a «digital twin».

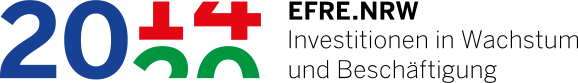

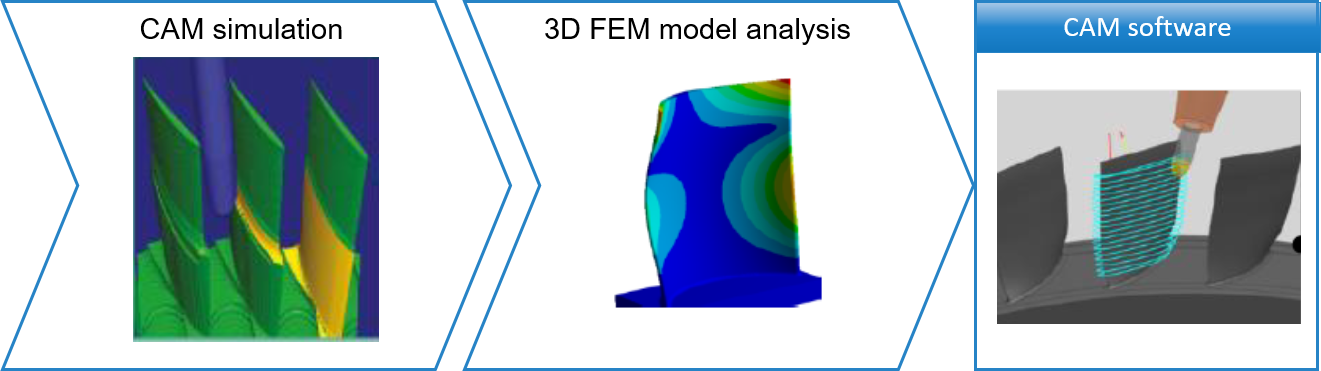

PhysiX-CAM allows the extraction of a high-quality representation of the current state of the part (In-Process-Workpiece – IPW) by the novel volumetric modelling approach »Swept-volume«. The high quality IPW is being combined with a FE-Software to simulate the local static and dynamic part deflections for different states of manufacturing. Process parameters can be enhanced by the usage of PhysiX-CAM thus realizing a higher efficiency in the milling process while maintaining the resulting surface quality.

Currently available software solutions do not consider the current state of the work piece in their calculations or provide a representation which lacks the necessary precision like the multi-dexel approach. In comparison the swept-volume approach allows the seamless use of this part representation in FE-simulation allowing the calculation of optimized process parameters hence increasing the efficiency of the manufacturing process.