The complexity of industrial manufacturing processes and requirements for seamless automation increase constantly in the context of global competition. To stay competitive, not only innovative technologies have to be utilized, but also appropriate support by custom-tailored software tools and automation solutions is necessary to align process steps to each other, to plan these steps and prepare them. Depending on varying complexity of involved manufacturing technology and other circumstances CAD/CAM activities as well as process preparation can take up to 35% of the whole manufacturing time. Besides tedious referencing and metrology operations a substantial part of the planning step consists of CAD and CAM activities. Current software systems have reached a level of complexity that software users must put a lot of effort into handling the software to accomplish a certain result, without really being “productive”. Especially in the case of production of small lot sizes or adaptive processes, marginal changes in planning can have a tremendous effect on reduction of machine operating times. The automation of involved manual process steps, e.g. part referencing, in combination with the use of a precise simulation environment can in this context pose a huge improvement in efficiency and eventually in machine operating times.

Our Vision

Knowledge can be encapsulated in custom-tailored software solutions, providing a high ease of use and re-use. We, at AixPath, support our customers in their endeavors to increase the efficiency of their production using custom-tailored software and sophisticated software solutions. Our software and engineering team has intensive experience with manufacturing technologies, PLM systems, application areas and machine tools. We are well versed with the potentials and involved challenges when implementing holistic seamless process chains. Furthermore, we strongly cooperate with research institutes in research [Read more – Link Research projects] and commercialization projects and provide our partners and customers a systematic and efficient transfer of latest state of the research and development during prototypic implementations as well as maturing software solutions into regular production processes.

Our Services

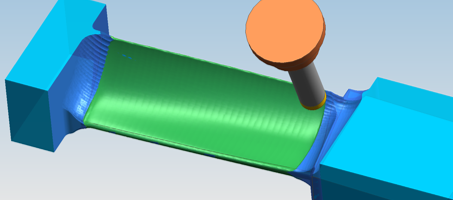

Our team offers not only offers experience in the state-of-the-art software engineering techniques and area of programming languages but also possess a strong background in production engineering with intensive knowledge and experience in subtractive and additive manufacturing technologies. Our automation and CAD/CAM solutions implement process steps and chains for a broad variety of manufacturing technologies including:

- Milling

- Turning

- Grinding

- Polishing

- Water jet cutting

- Ultraprecision Grinding

- Powder Bed Fusion

- Direct Energy Deposition

- Fused Deposited Modelling

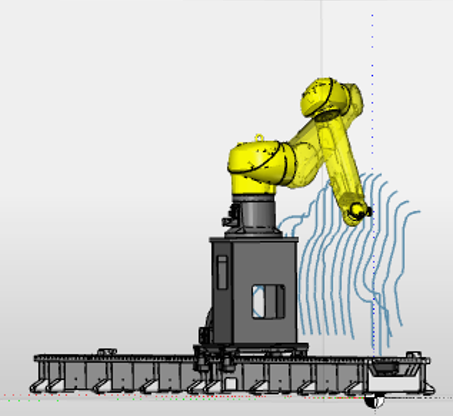

Furthermore, our software products can be configured to work with most metrology and robot systems, CNC and additive work centers and provide besides pure G-Code a variety of proprietary languages and control protocols for machine tools and peripherals. With our partner’s kinematic and material removal simulation, we are capable to map precisely different axis kinematics of machine tools and to simulate and optimize processes of a variety of process technologies. Our software products allow us the simulation and control of machine tools and robots from the following manufacturers:

- Siemens

- Heller

- Alzmetall

- Haidenhein

- Zeiss

- Nikon

- Fanuc

- Stäubli

- ABB

- Universal Robots

- EOS

To guarantee the correct functionality of the simulation environment and the post processors, we also provide calibration procedures for different machine equipment as well as automated solutions for referencing and metrology tasks to obtain the alignment or topography of the work piece. We are happy to measure and calibrate your machine equipment with our certified partners and provide you with a virtual duplicate of your manufacturing environment.

We are glad to help our customers define requirements for their software and automation solutions and provide them with custom-tailored software solutions integrated into their PLM infrastructure. Our standard integrations are currently available for Siemens NX. Other systems are available on request.

We are glad to help our customers define requirements for their software and automation solutions and provide them with custom-tailored software solutions integrated into their PLM infrastructure. Our standard integrations are currently available for Siemens NX. Other systems are available on request.

AixPath provides due to our interdisciplinary background software solutions for a multitude of application areas and manufacturing technologies:

We are looking forward to helping You automate and efficiently implement your innovative manufacturing solution and accompany You on the journey from requirements specification to industrial application.

Our Team

DR. MARC STAUTNER

Material Removal & Kinematic Simulation

Dr. Riaz Ur-Rehman

Milling & Additive Manufacturing

THORSTEN SCHREINER

Control & Signal Processing

CHRISTOPH ZYMLA

Robotics & PostProcessing

OMER EHSAN

Metrology & Image Recognition